Western Specialty Contractor’s St. Louis Concrete Branch recently restored the concrete parking garage at 400 Chesterfield Center in Chesterfield, … [Read more...] about 400 Chesterfield Center | Chesterfield, MO

offutt

Scott Haas Promoted to Southeast Region 6 Manager

Western Specialty Contractors has promoted Scott Haas to Southeast Region 6 Manager. He served 10 years as Branch Manager of Western’s Springfield, IL Branch, … [Read more...] about Scott Haas Promoted to Southeast Region 6 Manager

The Mosaic | Dallas, TX

Western Specialty Contractors’ Dallas Branch completed a $2.1 million, two-year pinning project that included 20,000+ supplemental lateral anchors, shelf angle … [Read more...] about The Mosaic | Dallas, TX

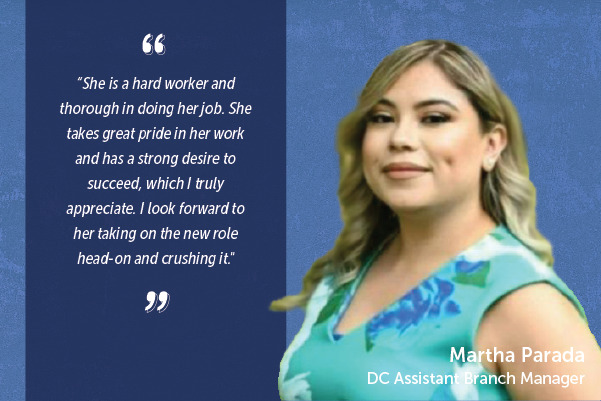

Martha Parada Promoted to DC Assistant Branch Manager

Western Specialty Contractors proudly announces the promotion of Martha Parada to Assistant Branch Manager of its Washington, D.C. Branch. Parada joined the … [Read more...] about Martha Parada Promoted to DC Assistant Branch Manager

Josh Woolard Promoted to Springfield Branch Manager

Western Specialty Contractors announces Josh Woolard’s promotion to Branch Manager in Springfield, IL. As Branch Manager, Woolard is responsible for managing … [Read more...] about Josh Woolard Promoted to Springfield Branch Manager

Quinn Griffith Promoted to Charlotte Branch Manager

Western Specialty Contractors is proud to announce the promotion of Quinn Griffith to Charlotte, NC, Branch Manager. As Branch Manager, Griffith is … [Read more...] about Quinn Griffith Promoted to Charlotte Branch Manager