Western Specialty Contractors has promoted Jessica Gitto to the position of National Account Manager. Gitto was previously the Marketing/Assistant National … [Read more...] about Jessica Gitto | New National Account Manager

Snow Removal 101 | Protect your Parking Structures this Winter

How do you prepare for the winter season? Having your snow removal provider follow these easy steps helps prevent and minimize unnecessary damage to your … [Read more...] about Snow Removal 101 | Protect your Parking Structures this Winter

Is Your Building or Parking Garage Prepared for Winter?

With the changing season comes freeze and thaw cycles, falling pine needles and leaves, organic growth and harsh weather conditions that can wreak havoc on a … [Read more...] about Is Your Building or Parking Garage Prepared for Winter?

Western Receives St. Louis Business Journal Family Business Award

Photo Credit: Dilip Vishwanat | SLBJ Western Specialty Contractors is honored to announce that it has been selected for the St. Louis Business Journal’s Family … [Read more...] about Western Receives St. Louis Business Journal Family Business Award

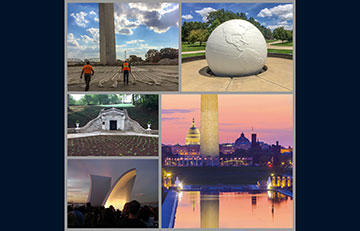

WESTERN USES SPECIAL SKILLS & CARE WHEN WORKING ON TREASURED MONUMENTS & MEMORIALS

Monuments can be powerful, inspiring tributes to a person, place, tragedy or event. But when those treasured monuments start to show signs of wear-and-tear and … [Read more...] about WESTERN USES SPECIAL SKILLS & CARE WHEN WORKING ON TREASURED MONUMENTS & MEMORIALS

Former Western Specialty Contractors COO Jim Rechtin, Sr. Passes Away

It is with a heavy heart that Western Specialty Contractors announces the passing of former Chief Operating Officer Jim Rechtin, Sr. on Sept. 17 following a … [Read more...] about Former Western Specialty Contractors COO Jim Rechtin, Sr. Passes Away