Photo Credit: Dilip Vishwanat | SLBJ Western Specialty Contractors is honored to announce that it has been selected for the St. Louis Business Journal’s Family … [Read more...] about Western Receives St. Louis Business Journal Family Business Award

Archives for October 2018

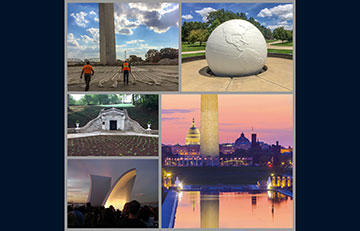

WESTERN USES SPECIAL SKILLS & CARE WHEN WORKING ON TREASURED MONUMENTS & MEMORIALS

Monuments can be powerful, inspiring tributes to a person, place, tragedy or event. But when those treasured monuments start to show signs of wear-and-tear and … [Read more...] about WESTERN USES SPECIAL SKILLS & CARE WHEN WORKING ON TREASURED MONUMENTS & MEMORIALS